1.high working efficiency and good chamfering effect

2.Good uprightness and precise size of processed tiles edges without break and chipping.

3.Individual formulation and grit match are available for different ceramic tiles quality.

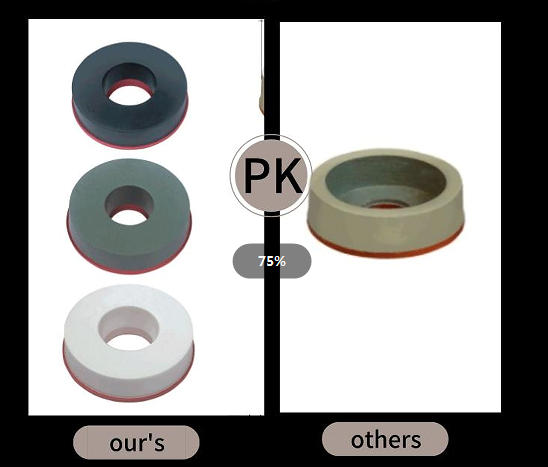

4.Strict production process control and stable quality.

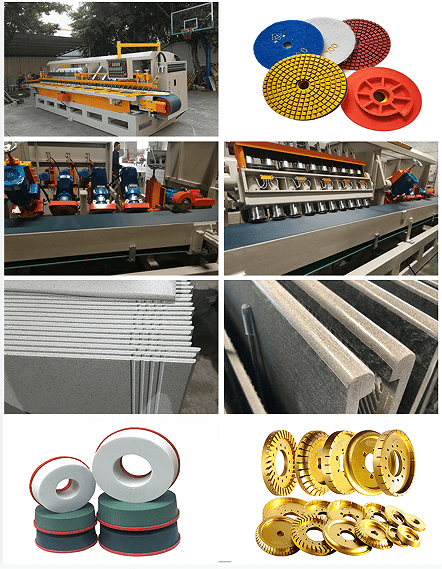

5. We can produce any required specs of diamond grinding wheels used on different ceramic grinding machines.

Diamond Chamfering Wheels are 45 degrees special polishing abrasive,they are used to make chamfering after squaring on ceramic tiles, whose function is to guarantee the safety in transportation and usage.

According to segment structure it is classified into Segment Chamfering Wheel and Continuous rim Chamfering Wheel. Segment Chamfering Wheel is used to make bigger corners normally before polishing on ceramic tiles because of their strong removing capacity. Continuous rim Chamfering Wheel is normally used to make chamfering after polishing.

According to the different bond used, it is classified into Metal-Bond Diamond chamfering wheel, Resin-Bond Diamond chamfering wheel and Resin-Bond Silicon Carbide chamfering wheel.

Our metal-bond diamond chamfering wheels are approved for their high working efficiency and good chamfering effect.

| Product name: | Diamond Chamfering Wheel For Polishing |

| Application: | make chamfering on ceramic tiles |

| Place of Origin: | Guangdong, China |

| Grit: | 0# 1# 2# 3# 4# 6# 8# |

| Material: | diamond and resin |

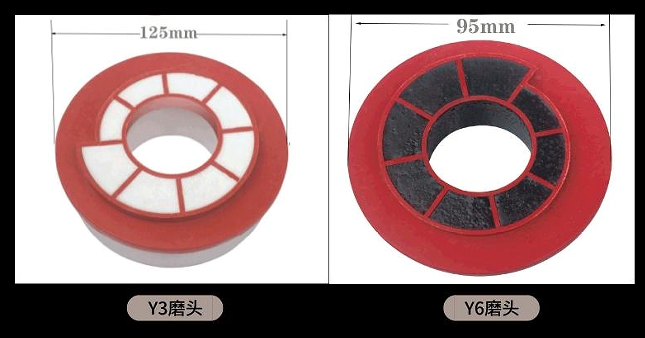

| Outer Diameter (mm): | 95, 125 mm |

| Customized support: | OEM |

| Usage: | Wet Working |